BBC Micro Model A/B General Maintenance

Appearance

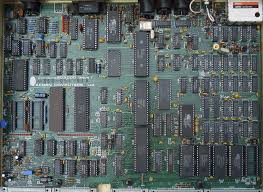

The BBC Micro Model A/B is a classic British microcomputer, now over 40 years old. Regular maintenance is essential to preserve its reliability, prevent avoidable failures, and ensure safe operation for years to come.

Regular Cleaning

[edit | edit source]Case and Keyboard

[edit | edit source]- Wipe the ABS case and keycaps with a damp microfibre cloth and mild soap. Avoid excess water near the badge or labels.

- Remove keycaps gently (vertical pull) for deep cleaning; clean plungers and springs with 99% isopropyl alcohol (IPA).

- For yellowed plastics, retrobrite is possible but monitor carefully to avoid warping or streaking.

- Lubricate the space bar stabiliser wire with plastic-safe grease if sticky.

Mainboard and Expansion Sockets

[edit | edit source]- Unplug the computer and allow capacitors to discharge for 5 minutes before opening.

- Use compressed air or a soft anti-static brush to remove dust from the mainboard, PSU, and connectors.

- Re-seat all socketed ICs (including ULA, CPU, ROMs) annually to reduce contact oxidation.

- Clean edge connectors (user port, 1 MHz bus, Tube, Econet) with IPA and a lint-free swab.

Power Supply & Voltage Checks

[edit | edit source]The BBC Micro’s internal linear PSU is robust but can fail with age, especially due to capacitor degradation.

Safety Precautions

[edit | edit source]- Never operate the PSU with the cover removed. High voltages are present.

- If the machine is unused for years, power up gradually using a variac or series bulb limiter if available.

Voltage Test Points

[edit | edit source]| Rail | Test Location | Expected Value |

|---|---|---|

| +5V DC | Any 74LS IC pin 14 vs pin 7 | 4.90 – 5.15 V |

| -5V DC | IC49 (SN76489) pin 1 vs GND | -4.75 – -5.25 V |

| +12V DC | IC11 (Video ULA) pin 24 vs GND | 11.5 – 12.5 V |

| Unregulated +18V | C9 positive lead | 17 – 20 V (varies with load) |

- Use a digital multimeter; check voltages before and after cleaning or repairs.

- If any rail is out of range, do not use the machine until the PSU is serviced.

Power Supply Refurbishment

[edit | edit source]- Replace all electrolytic capacitors in the PSU as a precaution (see below).

- Inspect for cracked solder joints, especially on the transformer and output connectors.

- Modern switch-mode replacement PSUs are available for the BBC Micro, but original units can be safely rebuilt.

Connector & Socket Corrosion

[edit | edit source]Age and humidity can cause oxidation on edge connectors, sockets, and switches.

Areas to Inspect

[edit | edit source]- IC sockets (CPU, ROMs, ULA, video, sound)

- Expansion edge connectors: user port, 1 MHz bus, Tube, Econet, disk drive

- Keyboard ribbon cable and connectors

- Power switch and rear panel connectors

Cleaning Procedure

[edit | edit source]- Apply DeoxIT or IPA to contacts; insert and remove ICs or cables several times to wipe oxidation.

- For persistent tarnish, use a fiberglass pen or pink eraser (gently).

- Inspect for green or white corrosion, especially on the user port and cassette socket.

Capacitor Health & Replacement

[edit | edit source]The BBC Micro contains both electrolytic and tantalum capacitors, some now well past their service life.

PSU Capacitors

[edit | edit source]- The RIFA X2 suppression capacitors (usually yellow or clear plastic, marked “RIFA”) are notorious for cracking and smoking. Replace immediately with new X2-rated parts.

- Replace all large electrolytics (e.g., C1, C2, C9) in the PSU to prevent voltage ripple and failure.

Mainboard Capacitors

[edit | edit source]- Replace any leaking, bulging, or crusty electrolytics (e.g., C9, C10, C31, C32, C37).

- Tantalum capacitors (e.g., C7, C8) rarely fail but can short-circuit catastrophically—replace if suspect.

- Clean any residue with IPA and repair corroded traces as needed.

Symptoms of Capacitor Failure

[edit | edit source]- PSU emits smoke or acrid smell (RIFA failure)

- Computer fails to power on, random resets, or video instability

- Audio hum, loss of sound, or video sync issues

Common Failure Points

[edit | edit source]| Component | Symptom | Notes / Quick Test |

|---|---|---|

| RIFA X2 caps (PSU) | Smoke, bang, burning smell | Replace all X2 caps on sight; do not power up until done |

| IC sockets (esp. ULA, CPU, ROMs) | No boot, random crashes, “beeeeeeeep” | Reseat chips, clean sockets, check for bent pins |

| Keyboard matrix / ribbon | Dead keys, stuck keys, no response | Inspect cable, clean contacts, test with continuity meter |

| Video ULA (IC6) | No video, garbled display, missing colours | Swap with known good ULA if available |

| RAM chips (ICs 61–76) | “Language?” error, random crashes, coloured screen | Use RAM test ROM or swap chips |

| Power switch | Intermittent power, won’t turn on/off | Clean or replace switch; check for arcing |

| Speaker / sound circuit | No sound, buzzing, distortion | Check speaker, C31/C32, SN76489 (IC49) |

Device-Specific Subsystems

[edit | edit source]Cassette Interface

[edit | edit source]- Clean the cassette socket with IPA; inspect for corrosion.

- Use good-quality, azimuth-adjusted cassette recorders and tapes.

- Replace C31/C32 if loading is unreliable.

Disk Drive Interface

[edit | edit source]- Clean the 34-pin disk connector and check for bent pins.

- Inspect for dry joints on the disk interface header.

- For DFS/Econet upgrades, ensure ROMs are properly seated.

RGB/Composite Video

[edit | edit source]- Clean the RGB and composite sockets.

- If video is unstable, check C9, C10, and the Video ULA.

User Port, 1 MHz Bus, Tube

[edit | edit source]- Clean edge connectors; inspect for corrosion or broken traces.

- For unreliable operation, check for dry joints and reflow as needed.

Cooling and Ventilation

[edit | edit source]- The BBC Micro is passively cooled. Ensure vents are clear and do not block airflow.

- In hot environments, consider adding a low-noise 5V fan inside the case, powered from the user port (observe current limits).

Recommended Tools & Consumables

[edit | edit source]- ESD wrist strap and anti-static mat

- Digital multimeter (for voltage and continuity checks)

- Soldering station with fine tip, flux, desolder braid

- DeoxIT or high-purity IPA for contact cleaning

- Fiberglass brush or pink eraser for edge connectors

- Replacement X2 safety capacitors (RIFA), electrolytics, and tantalums

- Small Phillips and flat screwdrivers, spudger for keycap removal

- Diagnostic ROMs (e.g., “Test ROM”, “Acorn Diagnostic”)

Preventive Maintenance Checklist

[edit | edit source]- Inspect and replace RIFA X2 capacitors in the PSU before first power-up.

- Check all PSU output voltages (+5V, -5V, +12V) before connecting peripherals.

- Clean and re-seat all socketed ICs; treat sockets with contact cleaner.

- Clean edge connectors (user port, Tube, etc.) annually.

- Inspect and clean keyboard matrix and ribbon cable.

- Replace mainboard electrolytic capacitors if leaking, bulging, or over 40 years old.

- Check for dry joints on the PSU, connectors, and expansion headers.

- Maintain good ventilation—keep vents clear and avoid stacking equipment.